The establishment of a DOT mandated damage prevention program will enable the prevention of 100% of all accidents involving excavation equipment and pipeline damage. Unfortunately, a large number of pipeline companies believe that they don’t have to respond to incoming requests for line location (One-Calls) or perform such activities as depth of cover surveys.

The establishment of a DOT mandated damage prevention program will enable the prevention of 100% of all accidents involving excavation equipment and pipeline damage. Unfortunately, a large number of pipeline companies believe that they don’t have to respond to incoming requests for line location (One-Calls) or perform such activities as depth of cover surveys.

Statistics have proven that vigilant participation and the enforcement of a qualified damage prevention program saves lives and diminishes asset losses. To ensure that your company remains within DOT compliance and to protect the lives of those working and living near your pipelines, the following programs must be instituted.

Line Locating

Alpha’s electronic line locating technicians are specialists in the location of underground pipelines, cables, and conduits under concrete, in crowded right-of-ways and multiple pipeline corridors, under power lines, and virtually any terrain.

Our standard line locating service includes establishing the approximate depths of pipelines and underground obstacles. Our technicians will also paint marks on the ground above the line, probe, and mark the location with a lathe identifying the customer’s name, type of line, line size, and depth.

Should you choose, our technicians can also:

- GPS the location of your system and points such as PIs, valves, and obstacles.

- Provide a map of your system for your records or integration into your one-call system.

- Relocate markers that are not representative of the pipeline location.

Area Sweeping

Urban sprawl has forced the development of land that possibly contains multiple cross-country oil and gas transmission lines. Before developing a tract of land or preparing for the construction of a process unit, it is imperative to electronically “sweep” areas that may contain undocumented or abandoned piping or obstacles.

Alpha technicians utilize our standard line location equipment or incorporate the use of our cesium magnetometer for the most thorough survey.

One-Call System

49 CFR Sec. 192.614 & 195.442 Para. B states that:

“An operator may comply with any of the requirements of paragraph (c) of this section through participation in a public service program, such as a one-call system, but such participation does not relieve the operator of the responsibility for compliance with this section. However, an operator must perform the duties of paragraph (c)(3) of this section through participation in a one-call system, if that one-call system is a qualified one-call system.”

Alpha is prepared to become your qualified one-call system operator. This service includes processing incoming requests for line location and dispatching our technicians or notifying your field personnel. Our line locating services are also available on an as-needed or contracted basis for your one-call response.

Dig Inspections

49 CFR Sec. 192.614 & 195.442 Paragraph C Section 6 states that an operator must:

“Provide as follows for inspection of pipelines that an operator has reason to believe could be damaged by excavation activities.”

“The inspection must be done as frequently as necessary during and after the activities to verify the integrity of the pipeline.”

Inspection tool anomaly verification creates the need to excavate extremely close to your pipelines. Our inspection services allow us to become your eyes in the field while your field personnel tend to their daily activities.

Depth of Cover Survey

49 CFR Sec. 192.327 & 195.248 states that:Unless specifically exempted in this subpart, all pipe must be buried so that it is below the level of cultivation. Except as provided in paragraph (b) of this section, the pipe must be installed so that the cover between the top of the pipe and the ground level, road bed, river bottom, or sea bottom, as applicable, complies with the following table:”

Inland

Class 1 locations…………………………………………………………………………..….30”

Class 2, 3, and 4 locations…………………………………………………………………36”

Drainage ditches of public roads and railroad crossings………………….………36”

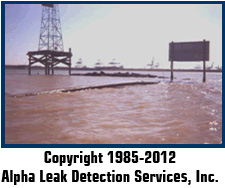

Navigable Water Crossings

Crossings of inland bodies of water with a width of at least 100 ft. from

high water mark to high water mark………………………………………………..…48”

Deepwater port safety zone……………………………………………………………..48”

Gulf of Mexico and its inlets and other offshore areas under water less

than 12 ft. deep as measured from the mean low tide……………………………36”

49 CFR Sec. 195.412 states:

“Except for offshore pipelines, each operator shall, at intervals not exceeding 5 years, inspect each crossing under a navigable waterway to determine the condition of the crossing.”

Floods, farming, and natural erosion carry away the soil necessary to protect pipelines from damage by livestock, motorized vehicles and equipment. Natural erosion and strong currents created by boats and maritime traffic also leaves pipelines exposed to damage by anchors and traffic during low tides or water levels.

Floods, farming, and natural erosion carry away the soil necessary to protect pipelines from damage by livestock, motorized vehicles and equipment. Natural erosion and strong currents created by boats and maritime traffic also leaves pipelines exposed to damage by anchors and traffic during low tides or water levels.

To help prevent natural disasters and asset loss, our technicians will locate your pipeline and determine the current depth of soil coverage. Alpha also provides professional divers and land surveyors to gather data during the execution of your navigable water crossing surveys. Our staff of engineers can then produce CAD profiles when required or requested for your record retention.

Case Studies

Enbridge – Conducted 5-year Navigable Water Crossing Survey at Freeport, TX ship channel and Texas inter-coastal waterways. Prepared CAD profiles for compliance documentation.

Kinder Morgan (Houston, TX) – Permanent One-Call technicians on premises.

Air Liquide – Located approx. 400 miles of 6” – 16” lines from Bay City, TX to Houston, TX including the Freeport area (located through marshland using airboats and amphibious vehicles).

Centennial Pipeline – Smart pig verification dig inspection for 650 mile 26” line from Longville, LA to Dietrich, IL.

The Alpha Solution

Alpha has nearly two decades of experience providing pipeline location services. Our clients continue to choose our professional services because they have all experienced the fact that we:

- Are professionals in the institution of qualified damage prevention programs.

- Relieve the crisis of internal resource shortages for personnel needed to complete extremely periodic and time-consuming activities.

- Abolish the cost and time required to secure multiple contractors to service the spectrum of your needs.

Each technician endures a rigorous training program and is annually evaluated and promoted based on his level of competency. This allows projects to be completed with limited or no client supervision.

We own and maintain a fleet of marine and all-terrain vehicles to enable our technicians to save time accessing remote locations and difficult right-of-ways. This equipment includes 4- and 6-wheel drive ATVs, shallow draft aluminum boats, barges, tractors, amphibious airboats, and marsh buggies.

We have national and international project experience and master service agreements (MSA) with some of the nation’s largest oil and gas production companies. To prevent damage to your pipeline system, put Alpha on your MSA list today.

Click here to discuss your needs with a qualified Alpha associate.