As described through NACE standard SP0502, External Corrosion Direct Assessment (ECDA) is a four turn-key process that covers the line through examination of places on the pipe where anomalies could form and thus corrode. This four step ECDA procedure which Alpha Pipeline Integrity Services strictly follows with NACE standard is:

- Pre-Assessment

- Indirect Inspection

- Direct Examination

- Post Assessment

Below is an example of how Alpha implements ECDA on a various pipeline.

Pre-Assessment

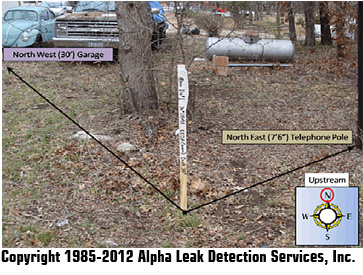

The Pre-Assessment starts with a detailed Right-of-Way inspection. All details are noted (CP Readings, ROW conditions, AOCs) including areas in which ROW maintenance is required as well as where it is in excellent condition.

Indirect Assessment Methods :

- Close interval survey (CIS)

- Direct current voltage gradient (DCVG)

- Alternating current voltage gradient (ACVG)

- Pipeline current mapper (PCM)

- C-scan

- Soil Resistivity

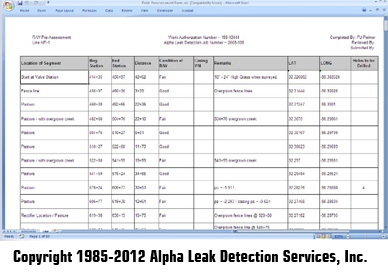

Presentation of Survey Data

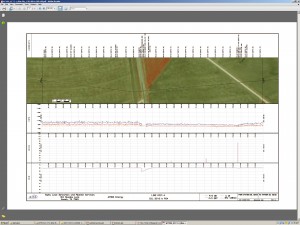

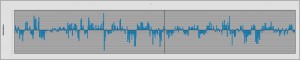

The latest software is used to align the data and present it with aerial imagery. After data has been collected and plotted, engineers examine the data by using various tools to decide which defects fit the criteria for verification.

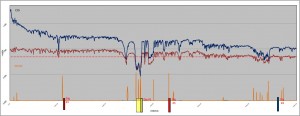

By overlaying the CIS data with the DCVG data, a more robust and accurate ECDA plan can be developed.

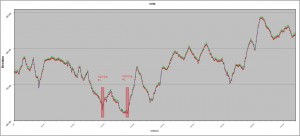

By using a combined Flow/Elevation Model, a more robust and accurate ICDA plan can be developed.

Direct examination:

- Coating conditions

- Corrosion mapping and data collection

- Pipe defects and metal loss

- Remaining strength of the pipe

- Soil type, pH levels, depth

- Cathodic protection evaluation

Anomaly Verification

Once the dig plan has been established and digs identified, technicians using Sub‐Meter GPS equipment return to the pipeline and stake the exact sites.

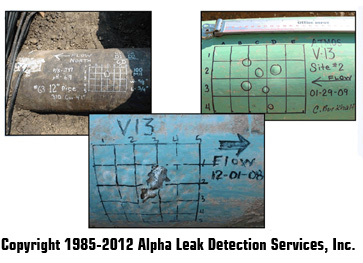

Technicians locate and document the defect found the Indirect Surveys by using Surveys.

The appropriate calculations are generated and repair calls are made.

Post Assessment

Once completed, all data is processed by Alpha’s engineers with the final report and recommendations completed and delivered to the customer.

Click here to discuss your needs with a qualified Alpha associate.