As described through NACE standard SP0502, ICDA is a four turn-key process that covers the line through examination of places on the pipe where liquids could form and thus corrode. This four step ICDA procedure which Alpha Pipeline Integrity Services strictly in conjunction with NACE standards is as follows:

- Pre-Assessment

- Indirect Inspection

- Direct Examination

- Post Assessment

Below is an example of how Alpha Pipeline Integrity Services implements ICDA on a pipeline.

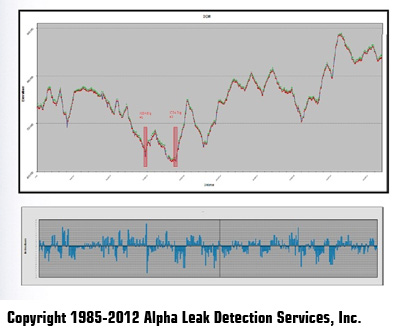

By using a combined Flow/Elevation Model, a more robust and accurate ICDA plan can be developed.

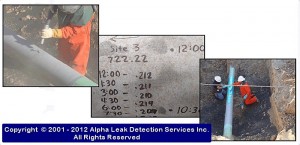

Once the dig plan has been established and digs identified, technicians using Sub-Meter GPS equipment return to the pipeline and stake the exact sites.

Once the excavation is performed, the technician confirms the existence of internal corrosion by performing wall thickness readings at the lowest position.

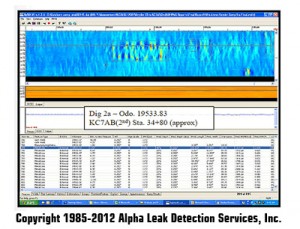

In Line Inspection (ILI):

Once the dig plan has been established and digs identified an confirmation of the area identified, extensive begins.

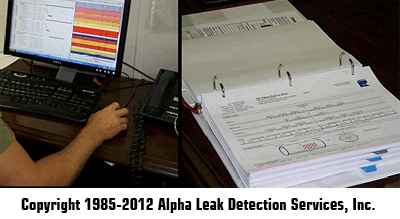

Once completed, all data is processed by the Back Office Support Staff and the final report and recommendation is completed and delivered to the customer.

Click here to discuss your needs with a qualified Alpha associate.