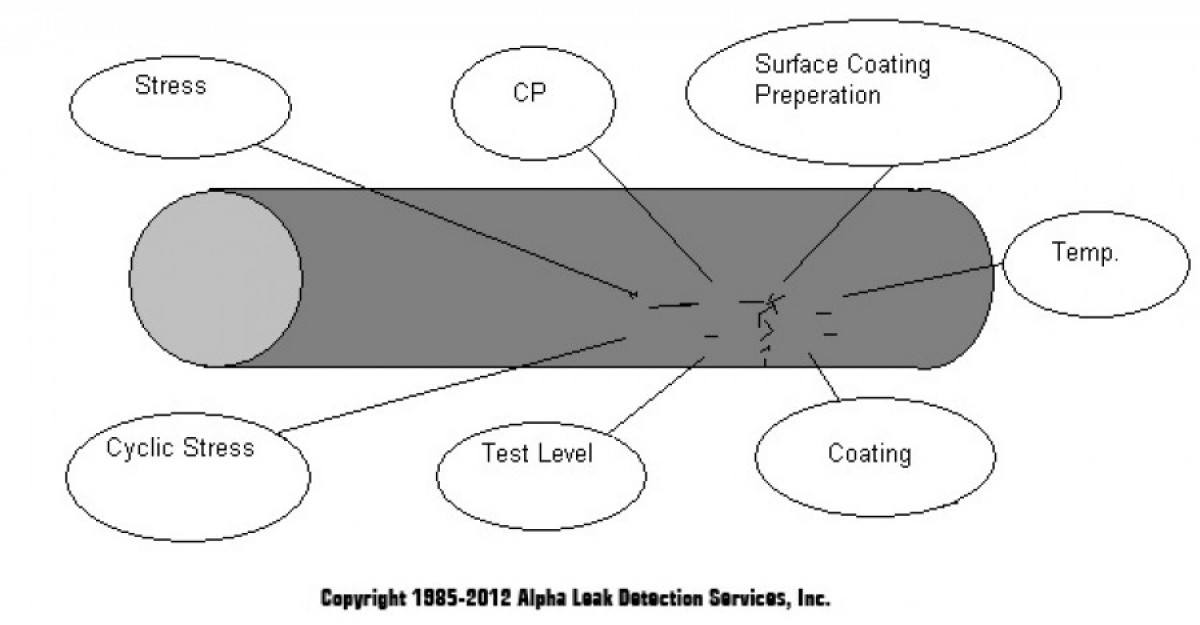

Stress Corrosion Cracking is formed from a corrosive environment as well as tensile stress placed on the metals of the pipe. Overtime (SCC) will crack the metal and significantly reduce the strength of the pipe which could lead to leaks, loss of valuable product, and blow-outs.

Stress Corrosion Cracking Direct Assessment (SCCDA), as defined by NACE Standard, is a DOT approved procedure that can identify areas where either near-neutral-pH or high-pH SCC can occur on external pipe surfaces. The SCCDA process is accumulated in four turn-key steps:

- Pre-Assessment

- Indirect Inspection

- Direct Examination

- Post Assessment

Once this process is complete, Alpha’s NACE certified and Operator Qualified (OQ) technicians will assess what stress corrosion cracking (SCC) mitigation is necessary by executing these actions:

- Coatings, soil, and moisture

- Surface coating preparation

- Maximum temperature

- Cyclic stress

- Stress level

- Cathodic potential level

- Test pressure level

Once these measures have been assessed, Alpha, under NACE SP0502 will then mitigate the SCC by:

- Applying CP

- Repair and apply coatings

- Replace or loop affected areas

Click here to discuss your needs with a qualified Alpha associate.